Tecnología, capacitación y consultoría innovadoras desde el diseño hasta la producción.

Tecnología

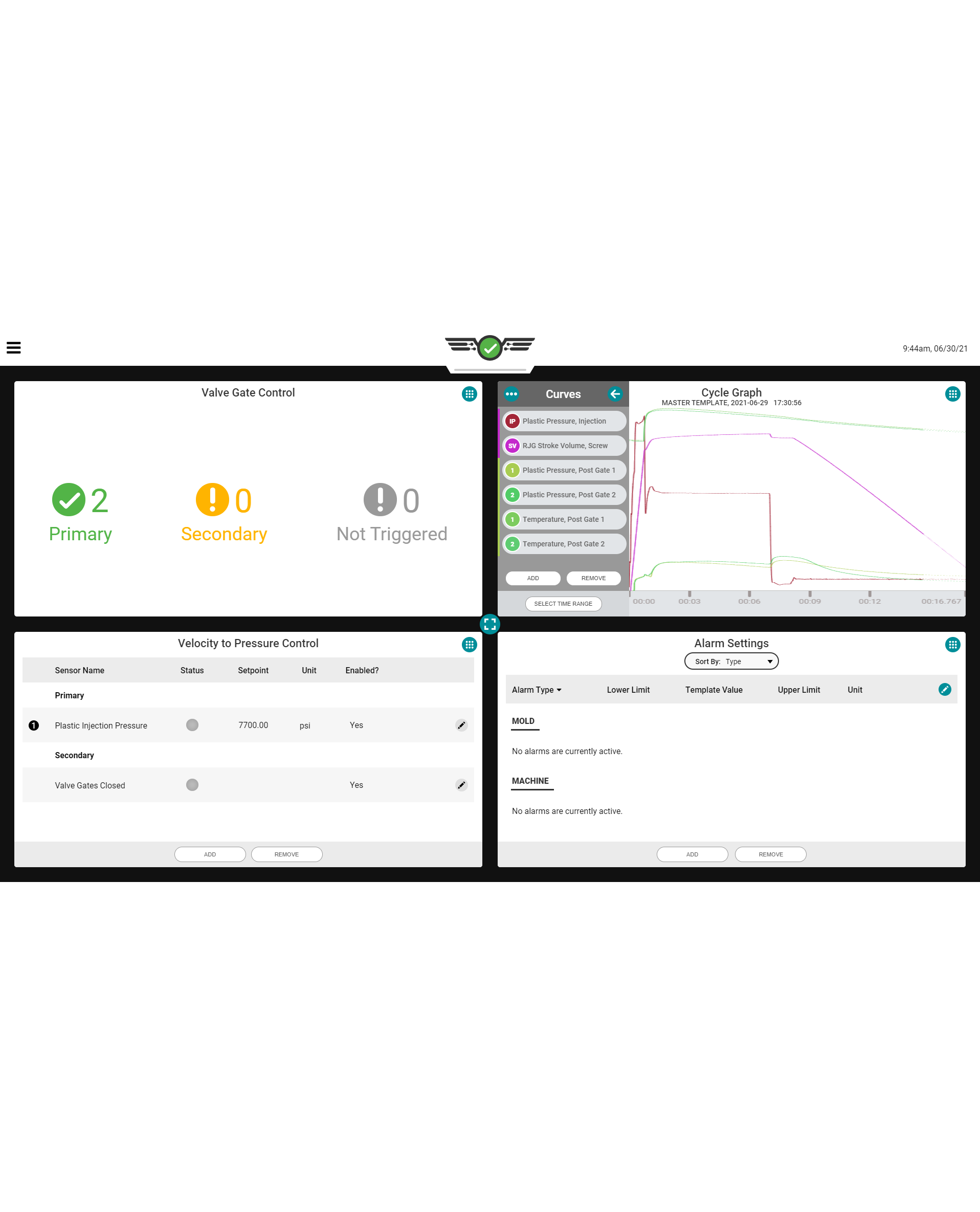

Obtenga una ventaja competitiva gracias al software de control de procesos más moderno de la industria, a la vez que mejora la productividad, minimiza los desechos y aumenta la rentabilidad. Nuestras soluciones tecnológicas personalizadas de servicio completo están diseñadas para resolver los problemas a los que se enfrenta todos los días.

Capacitación

Un personal capacitado mejora la calidad de los productos, la eficiencia, la moral y la rotación. Nuestros cursos de capacitación a nivel mundial, en persona y en línea, son impartidos por expertos del sector con experiencia práctica en el moldeo por inyección y se adaptan a sus necesidades específicas.

Consultoría

Aproveche la amplia experiencia que tienen nuestros consultores en la industria para resolver problemas constantes en procesos ya establecidos. Reduzca los desechos desde el diseño hasta las piezas con lanzamientos optimizados de herramientas para que pueda empezar a producir piezas buenas desde el primer disparo.