Tip of the Day 33: How to Deal with Bad Injection Forward Signals

On some machines the signal wired into the sequence module for injection forward may not behave as specified (on at start / off at end). Sometimes the signal goes on twice or has little bounces in it etc. The sequencer tries to ignore a lot of this stuff. For example, if the screw run signal is available it will ignore any second injection forward turn-on signals until after the screw stops.

Even at that there may be problems with the signal. On one machine we had the start of injection signal vary about ± ½ second from shot to shot. On another it had a little bounce at the beginning that caused the eDART to think the injection forward was on for ¼ second.

Here are some methods for dealing with these problems. Use the “Sequence Settings” “Injection” page

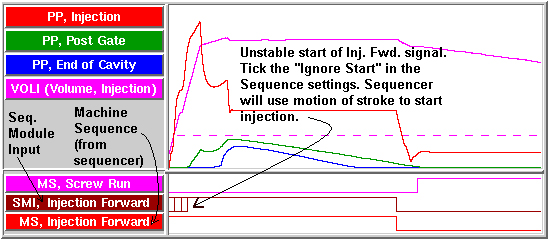

- If the start of the signal is flaky, tick the “Ignore Inj Fwd. Seq. Module Input at Start”. The eDART will use screw motion (or injection pressure, if no screw) to determine the start.

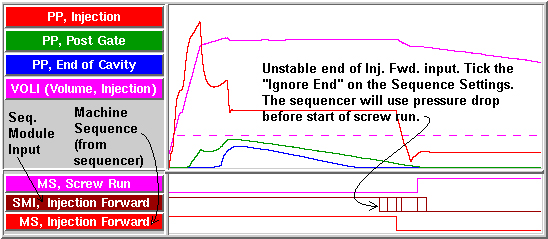

- Likewise if the end of injection is not stable or does not really go off at the end of injection tick the “Ignore Inj Fwd. Seq. Module Input at End”. The eDART will then use the falling pressure (corner or threshold) to figure out where injection ends.

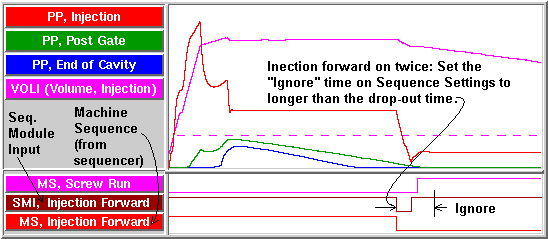

- If there is no Seq. Module Input / Screw Run then you may have to change the “Ignore injection forward OFF->ON setting if Seq. Module Input / Injection Forward comes on twice. Set the ignore time long enough so that the eDART does not “see” the second event.

- If the Seq. Module Input / Injection Forward never goes on or if it is completely useless (on – off – on – off noise) then in Sensor Locations set it to “Not Used”. This is the same as ignoring both start and end on the Sequence Settings page but is a better record of what happened.

- If there is no Seq. Module Input / Injection Forward or if you ignore its start or end then other values appear on the Sequence Settings page. These are used to try to make educated guesses as to the start and end of injection. Most of the default values work on most machines.

All of these various settings get saved with the machine. They should only have to be set once on a machine and then are memorized.

Graphical Aids