Tip of the Day 113: Redux

After publishing tip #112 I received some comments from readers asking why not just set the hold pressure to zero to make a fill only part. One customer said that they set the hold pressure to zero (without changing the hold timer) because the machine response is more like the actual machine response during a full cycle (with hold pressure).

Well, these comments make sense (thanks, C. N.). So this tip offers a clarification or some fine points on the discussion.

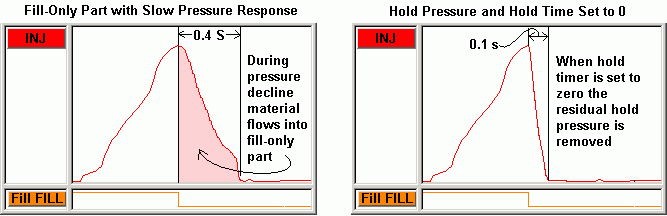

Moral of tip #112 is that you need to know your machine. The C. N. pointed out that his machine’s pressure profile for a fill only part is different when setting the timer to zero than when setting the hold pressure to zero. Here is what it might look like FOR SOME MACHINES:

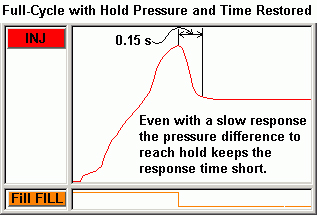

In the above in the fill-only part (with hold timer) there is plenty of residual pressure for a considerable time after transfer. Setting the hold timer to zero changes the machine response and prevents extra filling. This raises the concern about whether changing the hold timer and the machine response causes a different sort of response when hold is restored.

From above, the actual response time to get to hold during a normal cycle is considerably shorter than the residual pressure time when hold pressure is set to zero (and the time not zero). So the fill-only part with no hold timer (on this machine) may be closer to what is actually going on in the full cycle.

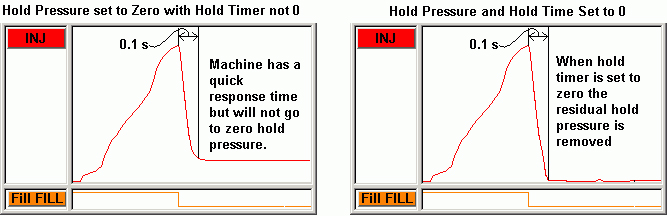

Another example in which you need to use the hold timer is a machine that will not let you set the hold pressure to zero. Some machines have a minimum hold pressure.

In the above example you can set the hold pressure to a true zero ONLY by setting the timer to zero as well.

Conclusion:

If your machine will drop hold pressure to zero and do it quickly, do not use the hold timer when making fill-only parts. If it will not the the using the hold timer to get rid of hold pressure my be your only option.