Tip of the Day 76: Stable vs. Whole Hold Pressure

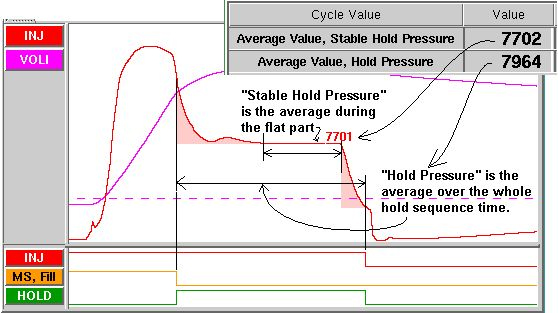

As mentioned in Tip #74 you can pick two different hold pressure summary values that represent hold pressure: Average Value / Stable Hold Pressure or Average Value / Hold Pressure. Each has a particular use. Here is a graphical description of how the eDART computes the two values.

Note that Average Value / Hold Pressure is computed correctly when the fill volume is set.

The two values are not dramatically different. This is because the extra increase in the average value over the slow transition at transfer is somewhat negated by the slowly declining hold pressure slope at the end of hold (the two pink areas). So the average value and stable value are similar. If the pressure dropped quickly at the end of hold the the Average Value / Hold Pressure would be significantly greater than the Average Value / Stable Hold Pressure.

Average Value / Stable Hold Pressure

Use this value to study whether someone has set the machine’s hold pressure setting to the proper process setting or not. This value only considers the flat part of the hold pressure curve and ignores droops or oscillations at transfer to hold or at the end of hold.

Average Value / Hold Pressure.

Use to determine whether the hold pressure as seen by the plastic may differ from machine to machine because of differences in the way the machine transitions to hold. This is not a precise measure of what the plastic sees because of the compression in the runner system. However if Average Value / Hold Pressure differs on the same mold template from one machine to another it should alert you to the fact that you have differently performing machines and may need to make a process adjustment to match between the two.

Additional Information

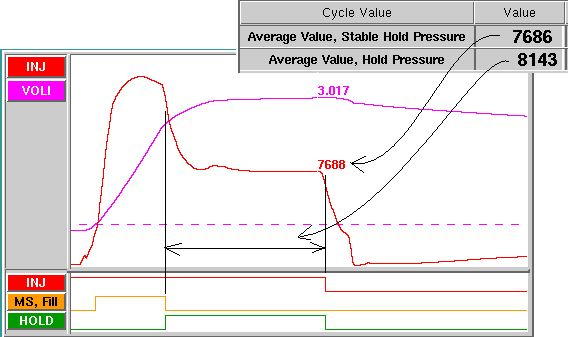

The graph below shows the difference in the two values if the hold sequence goes off when the machine ends injection earlier.

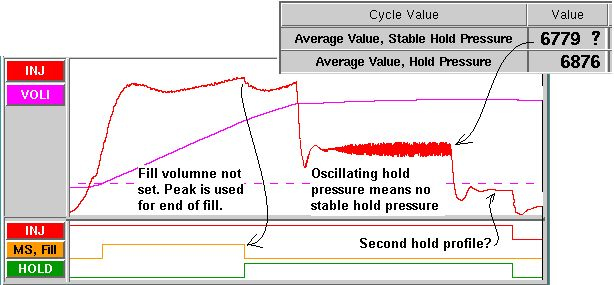

Here is an example showing three different problems.

Fill volume not set => hold comes on too early and includes the velocity controlled packing pressure in the Average Value / Hold Pressure.

The eDART cannot compute an Average Value / Stable Hold Pressure because the oscillations during hold are too great and the pressure is never stable. The value may come and go from shot to shot if the oscillations get lower on one shot and worse on the next.

If you have multiple hold pressures (profiled hold) then the eDART may not be able to determine which profile is the real Stable Hold Pressure.