Tip of the Day 65: The “Race” to sort on Cycle Time

The previous tips develop the idea of the “race condition” between the time the eDART puts out the sorting signal and the time the automation picks it up. To prevent a race there are ways to force the alarms to be computed early by setting a sorter integration limit or using end of screw run as the integration limit.

However there remain three values of type Sequence Time that the eDART cannot compute until the cycle ends: Cycle Time, Mold Clamped and Plastic Cooling. This is because the eDART does not know the length of the cycle until it ends. With Mold Clamped in use (defined in Sensor Locations and working) the end of the cycle is when Mold Clamped goes off. This is also assumed to be when plastic cooling ends.

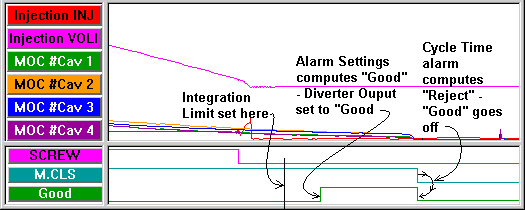

The eDART software is designed to sort of “change its mind” at the end of the cycle if you set a sorting alarm on one of these values. It is possible that the alarms on other values (e.g. cavity pressure or temperature) will indicate a good part but the cycle time will be too long. Some customers have set an alarm on Sequence Time / Cycle Time in order to prevent a long cycle from delivering a part with degraded material (due to residence time). In this case the “Good” output may go on at the integration limit and then off again at the end of Mold Clamped as shown below.

Furthermore the computation of alarm and change of output at the end happens very fast. This is because the eDART only needs to compute and compare three times. “This can take only fractions of a thousandth of a second. So the change in the “Good” output can happen simultaneously with the mold clamped signal going off. If the robot is looking for the signal at or before mold clamped then it will miss the change from “Good” to not good.”

Another Method for Rejecting Long Residence Time Parts:

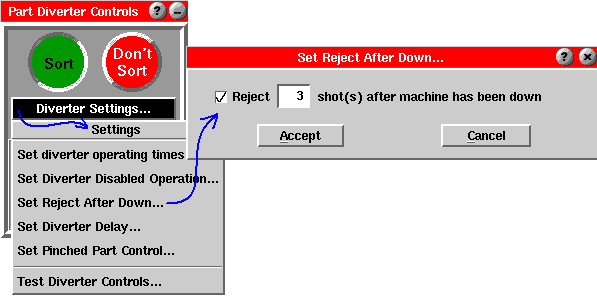

Suppose your automation cannot react properly to these changes in alarms (or the race between Mold Clamped off and the change in Good output). The eDART now contains a feature in the Diverter Controls (as of Release 8.0) that lets you tell the eDART to reject a certain number of parts after down.

The eDART assumes the job is down if 30 seconds elapse after the time the next cycle should have started. You can use this method instead of setting a sorting alarm on Cycle Time. This will reject as many parts as necessary to “clean” the barrel of degraded material.