Tip of the Day 101: Preemptive (human) Control using Warnings

The previous tip is a reminder that there other uses for the “Warnings” on the Alarm Settings tool. The “Warnings” that you add to the eDART’s™ Alarm Settings tool originally came from our plans to encourage 3-way sorting: Good, Bad & Ugly (see tip # 5). Few customers, however, have implemented this strategy of sorting parts into 3 bins. Herewith a description of using warnings without 3-way sorting.

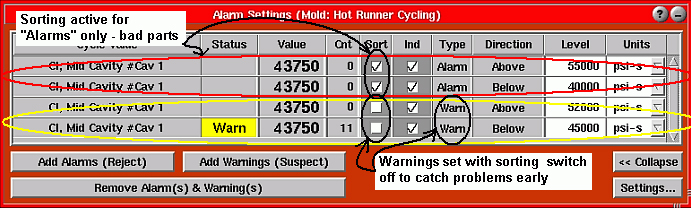

The essence is this: Set “Alarms” (rejects) with the “Sort” switch On to automatically sort bad parts. Set “Warnings” (suspects) with the “Sort” switch “Off” to detect changes before bad parts are made. You can then read the status on the system overviews. If the status is “Warning” you can preemptively solve a problem before any rejects are made or parts stick or the press shuts down. Here is an example with cavity pressure sensors sorting and warning:

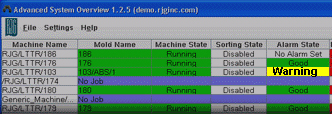

When observing the System Overview the supervisor notices a press with a “Warning” indicator on it

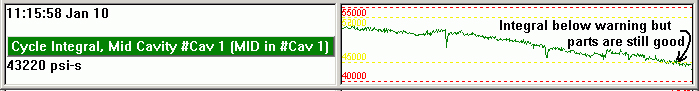

When he checks the summary graph on that press he can see that the parts are not yet being discarded but that they will be soon if he does not take action. In this case the action required was to clean the hot runner tips.

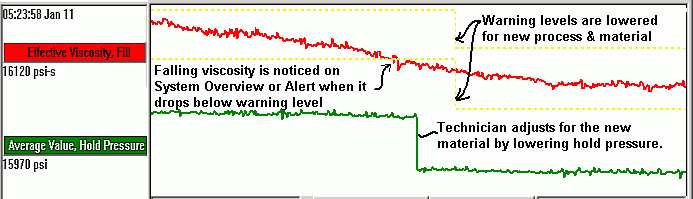

Warnings on Material Changes – Example without Cavity Sensors

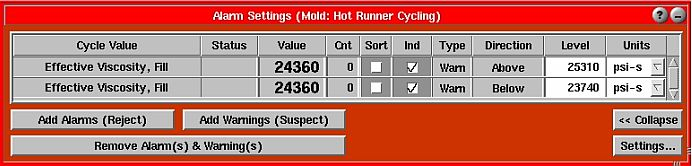

Effective Viscosity / Fill is a key variable to monitor because the material itself is one of the most uncontrolled variables in the molding process (tip # 45). Variations in viscosity affect different parts to different degrees. But it is wise to always know that variation is occurring so that you can check your product for quality. In this example we have set a warning on Effective Viscosity / Fill.

Next tip: Securing Individual Alarms