Tip of the Day 118: The Sample Output

You will find, when you try to sample parts, that sometimes they are hard to catch. Some customers have the rejects going straight into the grinder. So using the “Reject” switch on the Part Sampling tool is not helpful. Others have the robot placing parts, both rejects and good, in an inaccessible place. Thus when the Part Sampling tool tells you to “Take the next sample…” you have to perform a dance to wrestle the parts away from the automation equipment.

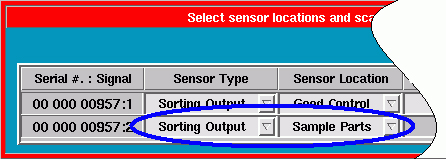

As a convenience the eDART can produce an output (OR2 contact closure) to tell the automation to put the parts in a special place. The output is called Sorting Output / Sample Parts. You set it up in the Sensor Locations window on a spare OR2 output as follows:

This output goes on at the start of the cycle when the Part Sampling tool says “Take Next Sample”. It goes off again after the data and note are written to the disk after the last sample is taken.

You can program the robot or conveyor to read this signal and place the sampled parts somewhere that you can easily access. You would click [Sample Parts] on the Part Sampling tool, walk to the part sample drop point, wait for the samples to be delivered and bag and tag each sample as it dropped out. This way you do not need to watch the screen or try to figure out which sample to take (that is being marked in the data) and which to ignore.

If you stop sampling before it is finished the Sorting Output / Sample Parts output goes off the instant that you confirm the stop.